+86 13630122007

+86 13630122007 CNC Machining Centers: Key Structures, Models & Features Explained

Below is a detailed professional introduction to mainstream models and their key features:

Ⅰ:Vertical Machining Centers

1.Hyundai Wia XF2000

As a 5-axis vertical machining center, it focuses on high-precision and high-speed machining. The rapid traverse speed of X/Y/Z axes reaches 50m/min, and that of A/C axes is 200r/min. Equipped with a built-in Electric Spindle with a maximum speed of 40000rpm and HSK-A63 tool holder, it minimizes spindle taper deformation during high-speed rotation. All axes are standard equipped with linear scales to compensate for thermal deformation of ball screws, and an oil cooling system maintains constant spindle temperature. The DDM worktable enables high-precision 5-axis simultaneous machining, suitable for complex curved parts such as impellers. The umbrella-type tool magazine offers a tool change time of 4.5 seconds, featuring a compact structure for easy maintenance.

2.Brother H550Xd1

A compact derivative model of horizontal compact vertical machining centers, it has X/Y/Z axis travels of 550/400/400mm and rapid traverse speeds of 50/56/56m/min respectively. The spindle offers an optional maximum speed of 16000r/min or a high-torque version, paired with a 30-tool magazine and high-speed B-axis worktable. Leveraging CAE analysis technology, it achieves a balance between high-speed performance and mechanical rigidity, supporting 7Mpa high-pressure Cutting Fluid. Ideal for efficient machining of small and medium-sized precision parts, its mechatronic design optimizes tool change and spindle acceleration/deceleration movements.

3.VMC850

A mainstream general-purpose vertical machining center in the industry, most configurations include a BT40 direct-drive spindle with 12000rpm and a 24-tool arm-type tool magazine. The X/Y/Z axis travels are suitable for machining small and medium-sized parts; linear guideway design ensures high-speed feeding, while some box-way models can handle heavy cutting. With balanced overall performance, it can process common materials such as steel and aluminum, as well as simple molds. It is highly popular in the mechanical processing industry, ideal for small-batch and multi-variety production.

Ⅱ.Horizontal Machining Centers

1.Starrag Heckert T45

A 5-axis horizontal machining center with X/Y/Z axis travels of 700/750/750mm, a feeding speed of 80m/min, a maximum turntable speed of 900r/min, and a tool change time of only 3.8s. Adopting a high-speed cradle mechanism with synchronous dual-side drive, it enables high-dynamic simultaneous machining, completing the overall processing of complex workpieces in one clamping. Compared with traditional 5-axis machines, the high-speed turntable expands capabilities for free-form surface and multi-angle machining. Its modular design allows flexible configuration while minimizing floor space, suitable for high-precision complex workpieces.

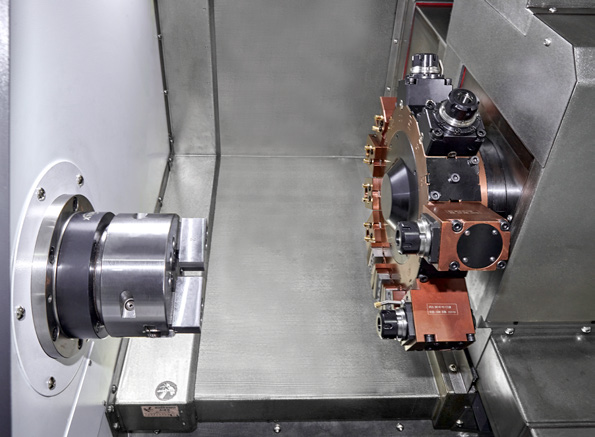

2.Grob G150

Frequently integrated with the GRC-R12 robot unit to form an automated machining cell, it has X/Y/Z axis travels of 450/670/665mm, an electric spindle with 16000r/min, 32kW power, and 206Nm torque. The robot unit can automatically handle workpieces weighing up to 2.5kg, with a maximum of 6 drawer-type material racks. Featuring high-precision cutting capabilities, it supports expansion from standalone machining to flexible production lines, suitable for batch automated machining of small and medium-sized precision parts.

3.Hengling HF5500

A 5-axis horizontal cradle machining center with X/Y/Z axis travels of 900/950/930mm, capable of processing large workpieces with a maximum diameter of 900mm and height of 870mm. Standard equipped with a rotary CNC turntable with support bearings and high-dynamic torque-driven AB axes, its new DC spindle balances high speed and torque. Integrating composite machining functions such as turning, hobbing, and shaping, the NC rotary worktable has low moment of inertia for fast positioning. Equipped with a pallet changing system for automated production, it is suitable for multi-process integrated machining of large complex workpieces.

Ⅲ.Gantry Machining Centers

1.Yishengtai YST-2010

A mainstream large gantry model with an X-axis travel of approximately 2000mm, Y-axis of 1000mm, and a worktable load capacity of about 2000Kg. Standard equipped with a BT50 spindle with a speed range of 6000-10000rpm, it adopts a high-rigidity gantry frame structure. Servo motor-driven ball screws ensure machining precision, compatible with CNC systems such as Fanuc and Siemens. Suitable for large plate and box-type parts in machinery and automotive industries, it stably performs heavy cutting processes such as milling and boring.

2.Yishengtai YST-2014

An extra-large heavy-duty model with X/Y/Z axis travels of 2000/1400/1000mm, equipped with an ultra-high torque spindle driven by a two-speed gearbox, offering optional 500rpm for heavy cutting or 12000rpm for high-speed machining, paired with a 60+ tool chain-type magazine. Adopting a modular reinforced gantry structure integrated with thermal compensation and vibration suppression technologies, its machining precision reaches ±0.003mm. Suitable for extra-large workpieces such as large frames and heavy bases in aerospace and rail transit industries, it supports 5-axis simultaneous machining expansion and 5-face machining.

3.Emco BAspace3

With X/Y/Z axis travels of 3000/1800/875mm and A/C axis travels of ±105°/±135°, the spindle has a maximum speed of 17500r/min. It features a patented SW monoblock frame bed, linear motors, and a two-axis rotary head, with a rapid traverse speed of 120m/min and acceleration of 2g. The single-spindle dual-worktable design is suitable for machining large-size parts such as new energy vehicle battery casings and body structural components. The X-axis gantry-driven design ensures stability during long-stroke machining.

Ⅳ.5-Axis Machining Centers

1.Fanuc 30i-B Plus

A core model of the high-end 5-axis control series, capable of controlling up to 96 axes and 24 spindle axes, suitable for complex multi-axis simultaneous machining scenarios. Focusing on high-precision control for 5-axis machining, it is paired with the intuitive iHMI and Manual Guide i programming systems to simplify complex program writing. Integrating dual safety check functions and dynamic compensation technology, it accurately controls free-form surface machining errors, widely used in the machining of complex parts for high-end equipment such as aerospace.

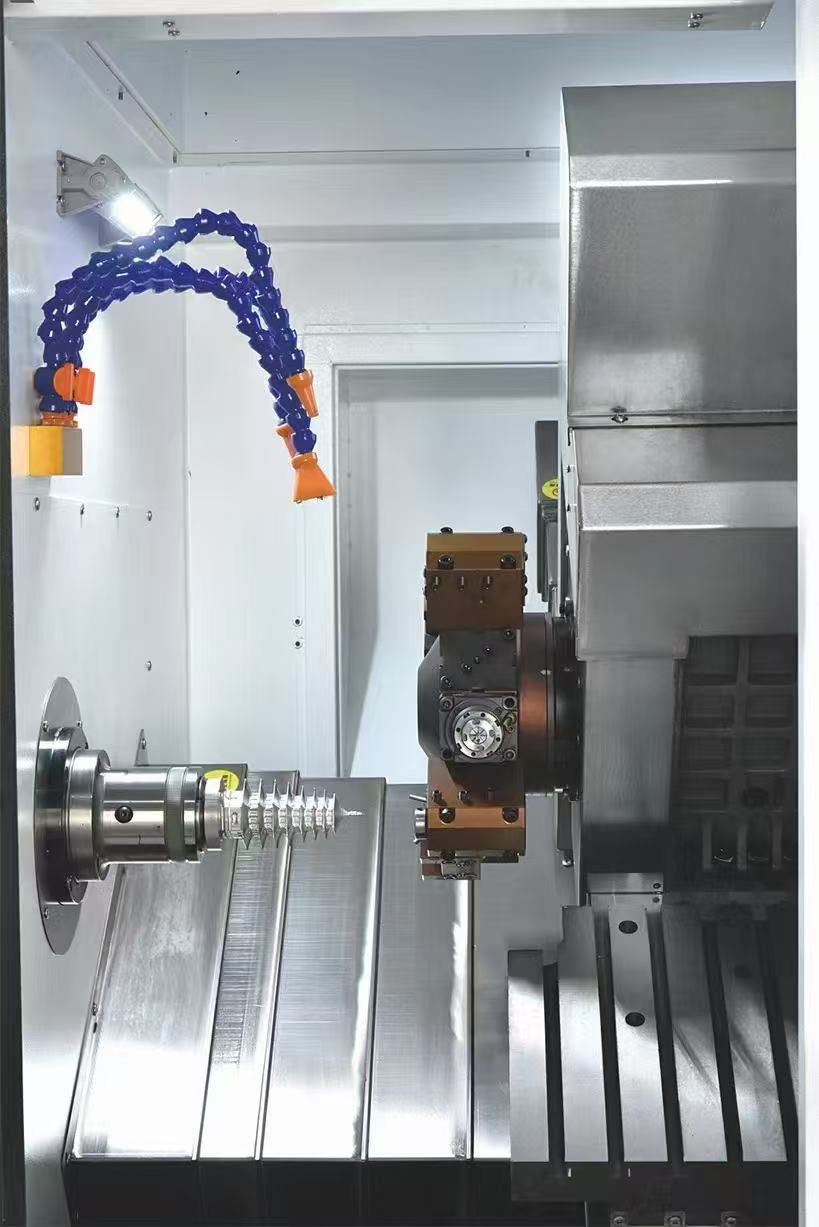

2.Grob G320G

A dual-spindle 5-axis machining center with X/Y/Z axis travels of 750/850/870mm, electric spindles with a maximum speed of 12000r/min and 206Nm torque. The parallel dual-spindle layout enables simultaneous machining of two workpieces of different models without additional loading preparation. Supporting multiple machining methods such as dry cutting, minimum quantity lubrication (MQL), and wet cutting, its modular design adapts to flexible production needs, suitable for efficient machining of small-batch and multi-variety precision parts.

3.Hyundai Wia XF2000i

An upgraded version of the XF2000, it adopts a chain-type tool magazine capable of holding 40 tools with a tool change time of 5.0 seconds. The X/Y/Z axes offer acceleration/deceleration of 1.2G, A/C axes have a rapid traverse speed of 120r/min, and the worktable size is expanded to Φ260mm. Retaining high-precision configurations such as the built-in electric spindle and linear scales, it is suitable for machining more complex molds and precision components. Compared with the umbrella-type tool magazine, the chain-type tool magazine is more suitable for batch machining scenarios.